中国CNC旋盤加工部品サプライヤー

CNC旋盤加工部品の特徴

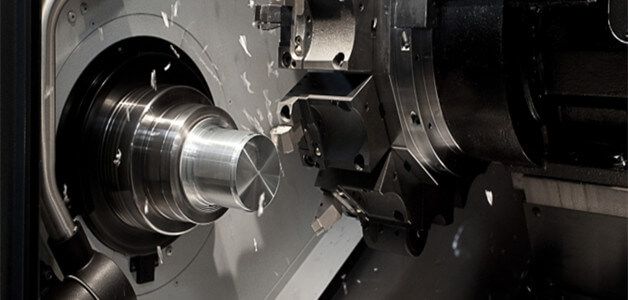

Operations for Producing CNC Turned Parts

Different turning operations can be used on the workpiece depending on your design. This requires the use of different tools. Common turning operations include:

CNC turning allows you to combine multiple operations to produce parts with complicated features. With live tooling capabilities, even more operations can be performed on the workpiece without moving it. This is important if you need a precision turned part.

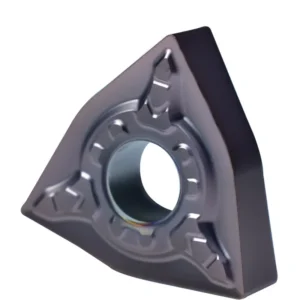

The workpiece is rotated while a single-point cutting tool moving parallel to it removes material from the side. This operation is used to produce features such as steps and chamfers.

The cutting tool removes a very thin layer of material to create a smooth surface finish.

A drill bit is used to cut a hole along the axis of the workpiece.

A boring tool is used to enlarge drilled holes or add features such as steps and chamfers inside them.

A single-point cutting tool is used to form threads on the outer surface of the workpiece.

A tool called a tap is used to cut internal threads in the workpiece.

CNC旋盤加工部品の材料選択肢

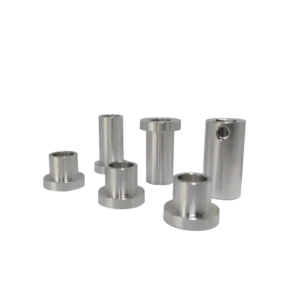

様々な産業向けのCNC旋盤加工部品

リード・プレシジョン・マシナリーの能力